For woodworkers, corroded machine tables are a very frustrating condition.

About ten years ago, Harvey took up this challenge.

By applying TiN PVD coating technology in the manufacture of the products, wear and manufacturing of the products, wear and corrosion on the sliding and drive wheel surfaces are reduced / eliminated.

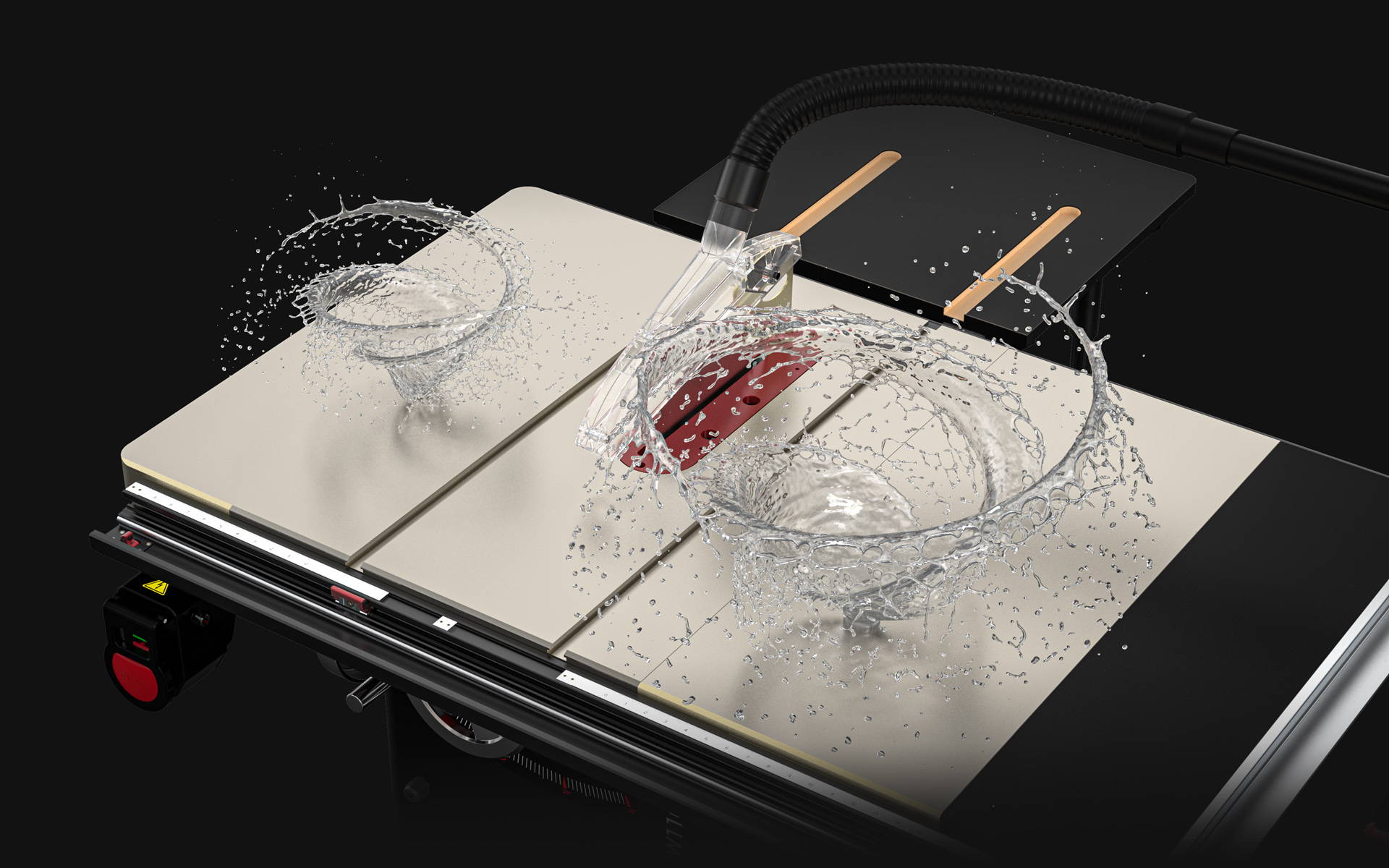

Harvey always strives for perfection. Five years ago, we began researching nickel-plating technologies. After countless attempts concerning process engineering and formulations, we have integrated an optimal, practical technology for the surface finishing of our saw table plates, wheels, pulleys, and not least, our dovetail pin systems into our production processes. This now guarantees the machine operator a literally "rust-free" experience.

In terms of application technology, the autocatalytic coating process is used here. Nickel, alloyed with a phosphorus component, serves as the coating material. These components significantly enhance the wear resistance and corrosion resistance compared to the base material, resulting in a smoother and more polished surface.

Our nickel-plated table surfaces have hardness levels exceeding 500 HV. This indicates a very high wear resistance. Self-conducted friction tests involving sliding wood materials on the nickel-plated surface consistently showed that the nickel layer effectively protects the table surface against abrasion. Additionally, the excellent sliding properties maintain a constant and low feed force requirement.

We also conducted high-temperature and acid corrosion tests to determine the service life of the nickel-plated surfaces. The results showed that, under normal operating conditions, the nickel-plated surfaces maintain their corrosion resistance for years, even in environments with high humidity.

We are convinced that the ALPHA HW110SE series table saws provide the ultimate solution to corrosion problems. Guided by our unwavering philosophy of "Good Enough is Not Enough," these saws exemplify our relentless commitment to innovation and precision. At the heart of this groundbreaking functionality is the innovative Big Eye cutting guide system, which has already revolutionized precision and user-friendliness in woodworking.

General Information about the HW110SE Series:

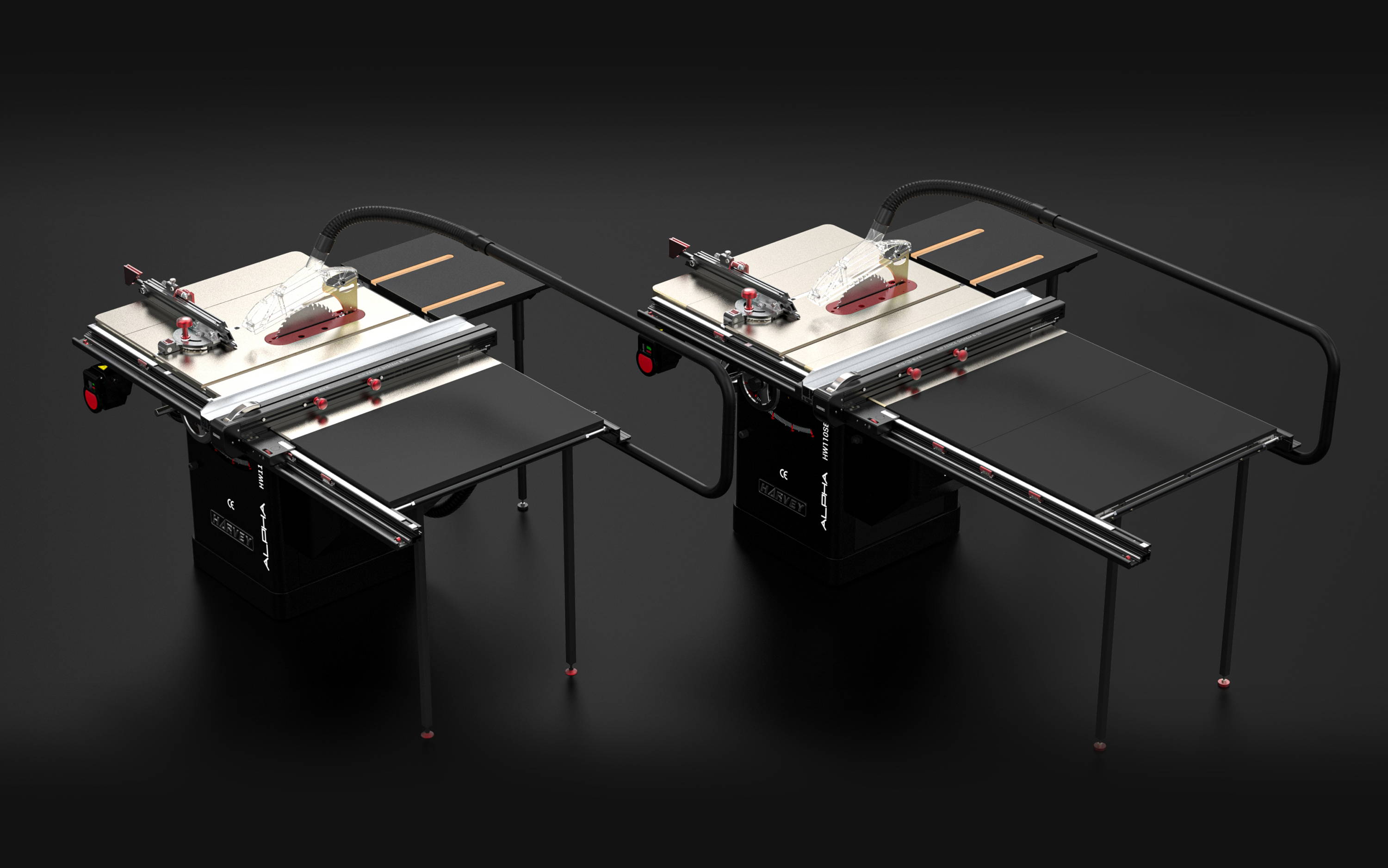

The HW110SE-36(T)/52(T) series table saws are the constructed proof of performance and precision combined with safety.

Depending on the model, the machines are equipped with powerful 2.2 kW or 4 kW spindle motors. All models in the series feature an MG-36 Pro M "COMPASS" miter angle stop, which allows for precise, 11-step adjustable or continuously variable angles for making miter cuts and angle divisions.

Also included in the delivery is the special transparent saw blade guard, designed for controlled, aerodynamic dust extraction.

The entire ALPHA HW110SE-36(T) / 52(T) series is manufactured to the highest technological quality standards. The HW110 series is not just about machine tools but represents innovations for your craft. Whether you are a hobbyist or an experienced professional setting up a woodworking shop, these saws offer the reliability and performance you need to elevate your woodworking projects to a new level.

* Extraordinary Nickel-plated Cast Iron Table

* Unprecedented BIG EYE Rip Fence System

* Industrial-grade DESTROYER General Purpose Blade

* MG-36Pro "COMPASS" Miter Gauge

* Powerful 2.2kW / 4kW TEFC Motor

* The Versatile Fence Positions

* Unique Dovetail Structured and Nickel-plated Trunnion System

* Dust Shroud Under Blade

* Special Transparent Blade Guard with Optimized Protection and Dust Control

* Built-in Dust Collection Hose System

* Magnetic Safety Switch

Superior Durability and Resistance: The table undergoes a chemical nickel-plating process that bonds the nickel layer thickly to the base material, reaching an impressive hardness range of 500 HV to 700 HV, significantly enhancing its durability and resistance to corrosion and wear. Extensive friction tests using wooden blocks consistently demonstrated that the nickel layer can effectively protected the table surface.

Additionally, we conducted a series of high-temperature and strong acid corrosion tests to evaluate the longevity of the nickel-plated surfaces. The results indicated that, under normal usage conditions, the nickel-plated surfaces could maintain their rust prevention performance for years. Notably, even in highly humid working environments, they exhibited exceptional rust prevention capabilities.

Extended Workspace:

A 800 mm deep table surface provides ample space for large pieces, ensuring safe and comfortable operation.

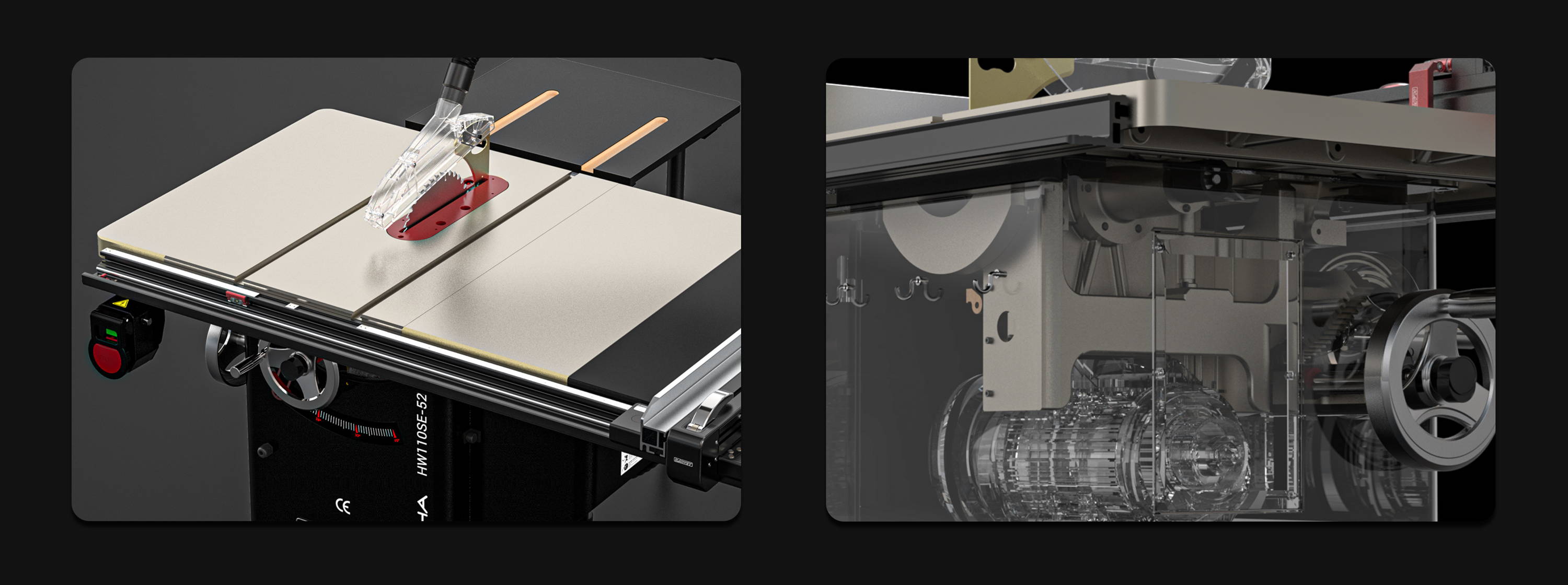

The entire Dovetail Structured Trunnion System has undergone a nickel-plating process, offering exceptional rust resistance and durability.

Additionally, we conducted a series of high-temperature and strong acid corrosion tests to evaluate the longevity of the nickel-plated parts. The results indicated that, under normal usage conditions, the nickel-plated surfaces could maintain their rust prevention performance for years. Notably, even in highly humid working environments, they exhibited exceptional rust prevention capabilities. This ensures rust resistance and longevity, making the trunnion maintenance-free for rust prevention.

The saw arbor is designed to meet industrial standards with higher accuracy, and can be easily disassembled, if needed.

The saw arbor is elevated by the dovetail trunnion system. The dovetail trunnion system provides a much more smoothness and cutting accuracy, however, less vibration.

The blade tilting is completed by the worm gear trunnion system with massive cast iron. The worm gear trunnion system makes the blade tilting smoother and more accurate.

An unprecedented rip-cutting solution for table saws

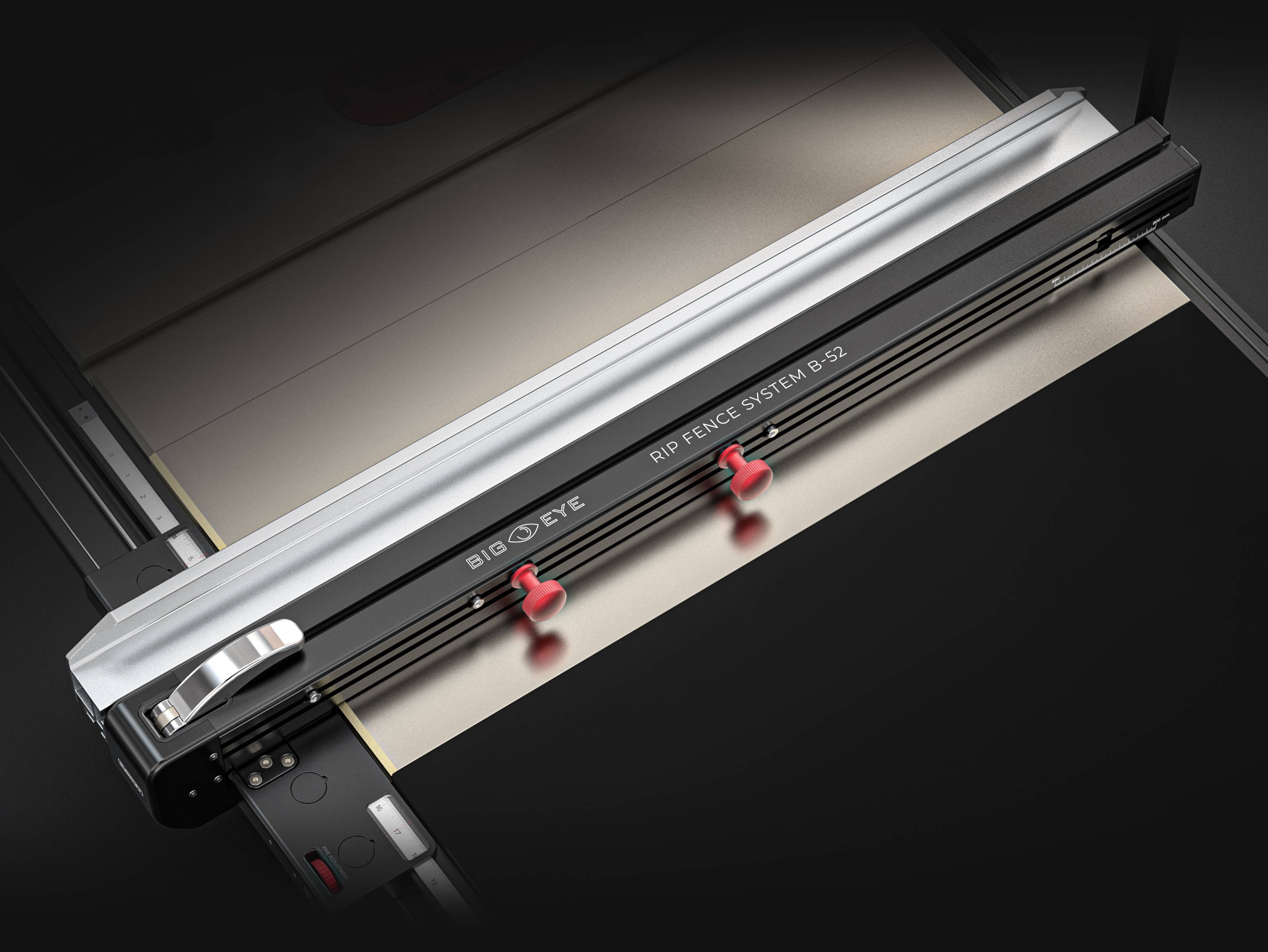

In order to elevate the user experience and operational efficiency of the HW110SE, we've integrated our cutting-edge BIG EYE Rip Fence System into the standard features of the HW110SE.

At the core of the Big Eye Rip Fence System lies the Dual-axis Linear Guide Rail System, featuring eight rollers with bearings that effortlessly glide along the two hardened and ground steel rods with zero clearance. This innovative design replaces traditional bushing sliding friction with smooth rolling friction, resulting in exceptional accurate fence movement (0.15mm in full length).

Dual-end Clamping controlled by the linkage mechanism

The innovative Synchronized Dual-end Fence Locking Mechanism enables simultaneous clamping of the fence on to the solid front and rear guide rail bodies, allowing for "Single Action" locking, and preventing the fence from deflective drifts during cutting. With the fence locked in place, the accuracy of the fence position remains within 0.02mm (0.0008"!).

The BIG EYE Rip Fence System also features a Micro-adjustment knob for extremely fine fence positioning with ease.

To achieve your streamline repetitive cutting tasks of various sizes, the BIG EYE Rip Fence System comes with four (4) built-in Flip Position Stops for your quick and comfortable operations.

The BIG EYE Rip Fence System introduces a very special scale viewer: The K9 Crystal Glass Window, boasting an impressive light transmittance of up to 92% and exceptional hardness, ensuring minimal visual errors (parallax) when reading measurements, offering superior durability and resistance to wear.

As a member of Alpha Table Saw Family, the HW110SE table saw definitely comes with the most popular COMPASS MG-36Pro Miter Gauge.

The unique structure of MG-36Pro ensures positive angle setting accuracy as high as 0.1 degree without need of adjustment.

Every part of the body and fence are made of T-6 aircraft-grade aluminum alloy and hardened steel, and each aluminum part is anodized with beautiful color and finish.

The standard 915mm crosscut fence equipped with an accurate flip stop and locking knob can meet most of your cutting demands.

Most importantly, COMPASS MG-36Pro is uniquely designed with a Quick-Action positive angle setting device which allows you to set ±60°, ±45°, ±30°, ±22.5°, ±15°, and 0° positive angles with single handed operation.

To enhance your woodworking experience and optimize HW110SE’ cutting performance, it also comes standard with the industrial-grade DESTROYER general purpose blade.

The BG52 Blade is designed to be a versatile blade that can be utilized on all types of cuts. The Hook Angle, Top Clearance Angle, and Top Bevel Angle are all designed to be 15°, which results in smooth finishes and high efficiency on both crosscutting and rip cuts.

The Destroyer BG52 254mm General Purpose Blade is an excellent choice for every woodworker. Its versatility allows you to achieve a smooth and stable crosscuts or rip cuts on any type of hardwood or softwood. With a versatile blade such as the Destroyer BG52, you won’t need to switch blades for different types of cuts, which will greatly improve your workflow and get things done quicker!

All the DESTROYER blade teeth are precision ground to ensure the accuracy of these essential angles.

The BIG EYE Rip Fence System features a standard high/low fence plate to accommodate different wood thicknesses. The high fence is designed for cutting thick wood, while the low fence is suitable for thin wood.

Switching between the two fence positions is effortless with the sliding scale.

The fence plate can be installed on either left or right side of the fence body, facilitating usage on both sides of the saw blade.

Additionally, the fence plate can be conveniently slid to the front of the saw blade, providing cross-cut positioning without the risk of kickback.

The blade guard with aerodynamic optimization improves the dust collection efficiency.

The special transparent blade guard provides visibility for aligning the saw blade with the intended line of cut. Both side barriers automatically adjust to the thickness of the advancing workpiece.

The patented "plug-in quick change" system allows you to change the blade guard and riving knife within a few seconds without the removal of the table insert.

Upper and lower dust collection is achieved simultaneously for clean and enjoyable cutting.

Y

The motor comes with the true OUTPUT POWER* of 2.2kW / 4kW, which is absolutely powerful enough to provide long term performance even in the toughest conditions.

*Note on output power:

The output power is the mechanical power at the motor shaft of a drive machine. Mechanical power on electric machines is generally reduced by multipliers such as the efficiency Ԑ (Eta) and the power factor cos φ (cosine Phi).

Influencing factors such as frictional resistance, coils through which electricity flows, thermal losses due to variable hot resistors and apparent power come into play here.

As with all other electrical machines, the electrically supplied power is always higher than the mechanically delivered power.

The magnetic safety switch with thermal overload protection can prevent the motor from being damaged by overheating.

To boost your efficiency when ripping wood on our HW110SE series table saws, we've outfitted the HW-110SE series with the RT-10A Rear Table as a standard feature.

The RT-10A Rear Table features two standard T-slots, a robust steel frame, an OSB tabletop and convenient installation.

The RT-10A Rear Table can be seamlessly attached to the rear guide rail, offering robust support at the back during your ripping tasks, enhancing both stability and safety.

This product is certified by the TÜV Rheinland

Optional Accessories

* Wide applicability and versatility.

* Unique dual fine-tuning mechanism provides the adjusting accuracy of 0.02mm.

* Equipped scale and flip stop present the accuracy and repeatability for a wide variety of cutting tasks.

* Zero clearance dovetail mechanism provides the perfect adjusting parallelism of the two fence halves.

* The fence made of anodized aircraft-grade aluminum extrusion is durable and provides great wear-resistance and superior hardness.

* Aerodynamically designed dust port and adjustable air inlet improve your dust collecting efficiency.

* Toolless adjustment makes your operation convenient and efficient.

* Premium cast iron table achieves a high flatness and superb stability.

* Industrial Grade Slider (1500mm/59” travel) assures clearance-free moving accuracy and consistent smoothness.

* Basically Stainless Steel, 6061 T-6 Anodized Aluminum Alloy and Brass provide extraordinary strength and rigidity.

* Laser etched vernier scale present you a visual aid to take an accurate measurement reading within 0.1 degree.

* Equipped Micro-Adjustable Flip Stop can provide the micro adjustments in 0.001" (0.02mm) increments.

* Positive Stops and Smart Trigger Lock can help you achieve the the precise angular settings fast and easily!

Works with Bridge City Tools

ALPHA HW110SE INSTRUCTION MANUAL-PDF DOWNLOAD

BIG EYE INSTRUCTION MANUAL-PDF DOWNLOAD

Explore Our Curated Selection of Accessories...